Since 2007

Conveyor Roller manufacturers In China

- Best Price & Large Quantity Discount

- Offers over 40 standard products and supports customization

- One-Stop production, No MOQ, fast delivery

With more than 18 years experiences in conveyor roller industry, Suzhou Yiyun Automation Technology Co.,Ltd. has advanced production facility and most 10+ years skilled workers, ensuring precision and quality in every product we deliver.

YUN Roller is a rapidly growing brand under our factory. We have standard and tailored conveyor rollers and serve you consultative way for innovative and cost effective rollers to meet your unique operation.

From communication to order confirmation, product production and processing and after-sales have exclusive engineers and you docking!

Optional Tube material Conveyor Rollers

Our conveyor rollers have a wide range of tube materials to choose from, including stainless steel conveyor rollers, carbon steel conveyor rollers,aluminum conveyor rollers, PVC sleeve conveyor rollers, PU cover conveyor rollers and rubber cover conveyor rollers

Our Hot-Sale Conveyor Rollers

Our options include gravity rollers, poly-vee rollers, O groove rollers, polymer or steel sprocket rollers, taper gravity or power rollers, lathe machining rollers, motorized rollers and others, all offering unique rollers. Plus, we can produce over 40 standard rollers and offer custom options too

Steel sprocket welded with tube ensures high torque transmission and durability, suitable for heavy-duty performance

- Driven: single/double sprocket

- Material: SUS/CSR/plastic cover

- Tube Std Dia: 50/60/76/80/89mm

- Shaft Std Dia: 12/15/20mm

- Temperature: -10° to +80° C

Low noise operation, anti-static or corrision-resistant, light to medium-duty conveying

- Driven: single/double sprocket

- Material: SUS/CSR/plastic cover

- Tube Std Dia: 38/50/60/76/80/89mm

- Shaft Std Dia: 12/15/20mm

- Temperature: 0° to +40° C

Suitable for curved conveyor, optional plastic sleeve. Flexible sizes fit for different special setups

- Driven: sprocket/poly-v/groove

- Material: SUS/CSR/plastic cover

- Tube Std Dia: 50+ mm

- Shaft Std Dia: 12/15mm

- Temperature: 0° to +40° C

High speed with low noise performance, O-belt driven system, load less than 300N, suistable for anti-static operation

- Driven: single/double groove

- Material: SUS/CSR/plastic cover

- Tube Std Dia: 38/50/60mm

- Shaft Std Dia: 10/12/15mm//11hex

- Temperature: 0° to +40° C

Different mounting way, spring load, bolt fixing and Snap-in mounting. Flexible sizes & optional material for specific operation

- Application: roller conveyor

- Tube Std Dia: 25/38/50/60/76/89mm

- Tube Thickness: 1/1.5/2/3mm

- Shaft Std Dia: 8/10/11hex/15/20mm

- Length: 60mm~3000mm

High speed with low noise performance, O-belt driven system in end, load less than 300N, end cap resist dust/water splash in

- Application: roller conveyor

- Tube Std Dia: 38/50/60mm

- Tube Thickness: 1.5/2/2.5/3mm

- Shaft Std Dia: 11hex/12/15mm

- Length: 60mm~2000mm

Electric roller, suitable for light-duty loading

- Application: roller/belt conveyor

- Material: SUS/CSR/PU & Rubber cover

- Tube Std Dia: 50/60/76mm

- Shaft Std Dia: 11hex/12/15mm

- Length: 100mm~3000mm

Fully Customizable

One-Stop Prdouction supports your Unique Rollers

- Types: Gravity/Poly-v/Motor/Sprocket/Groove/Maching Roller

- Tube Material: SUS/CSR/PVC or PU or Rubber Conver/AL

- Surface: Galvanized/Chrome Plated/Polishing

- Length: 50 to 3000mm(According to customer needs)

- Tube Thickness:1/1.5/2/2.5/3/4mm (Selectable)

- Color: Special colors can be customized

Conveyor roller advantages

Power Press Fit Technology

By controlling press force, detecting accurate interference fit to press the shaft into the roller, forming a high-strength mechanical joint. It makes sure quiet conveying.

Laser Tube cutting

Micron-level precision: laser spot size can reach 0.1mm, ensuring smooth and burr-free cuts. Reduce friction without scratchs on products and smooth conveying.

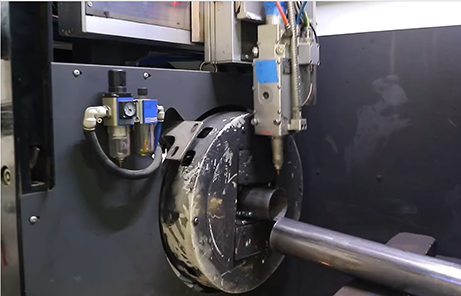

CNC Bending Machine

CNC controlled bending machine ensures angles and dimensions. Touchscreen CNC simplify adjustments and ensures robust construction for our assembly parts. Increasing Roller durability and increase roller longevity

Calibrate Roundness

Eccentric rollers may drift sideways, generate vibrations and loud noise when high-speed conveying, accelerate wear on bearings and support structures.

To prevent cascading failures.

Equiped with roller roundness calibration equipment, before shipment, QC inspector rotate rollers 360° recording max-min deviation (TIR) and strictly follow ISO9001 standard ensuring roller under tolerance demand

Calibrate Sizes

We have mechanical machines for control whole procedure, and each step with processing check.

In final product, our independent QC team check visually and also record the acutal data by using inspection equipments.

Our services

We have over 40 standard rollers and custom rollers for different applications. Contact us and you can get cost-effective rollers with uncompromising quality. We deliver quality and efficiency for every project.

Poly-Vee conveyor

Poly-Vee rollers

Curve Roller Conveyor

Double sprocket taper rollers

Roller Conveyor Unit

Double sprocket roller on 1 side.

Double sprocket roller on both ends.

Flexible roller Conveyors

O Grooved rollers

Roller Conveyors

Flanged double sprocket rollers.

Double sprocket rollers

Belt Conveyors

Motorized rollers for belt conveyors.

About YUN Roller

Founded in 2007, Suzhou Yiyun Automation Technology Co., Ltd. Yun Roller has advanced manufacturing machines, covering an area of 10,000 square meters, including 6,000 square meters of plant area.

Monthly output capacity of 20,000 units conveyor rollers to achieve significant cost reduction in raw material and fixed equipment spreading and promise fast turnaround delivery. With ISO9001 certification, we ensure cost-effective price without compromising on quality.

Wide ranges of standard types with selectable in material and flexible sizes and also tailored types for your specific operations.

Our products have earned a strong reputation globally, with successful sales across Europe, America, Australia, Southeast Asia, the Middle East. We continue to strengthen our presence in these regions, reflecting our ongoing commitment to help our clients catch more business !

Choose YUN Roller—where innovation meets excellence.

Our production environment

As a vertically integrated production specialist, we oversee the entire manufacturing process from raw tube material to finished assembly, ensuring seamless quality control at every stage. Our capabilities include precision tube cutting, welding, and assembly, backed by an independent QC department that rigorously inspects each step for consistency and reliability.

Tube Stock Area

Tube Unloading

Tube Laser Cutting

CNC Machining Area

Welding Area

Power Press Assemble

Professional, enthusiastic and reliable Conveyor Roller specialists

With 18 years of experience in conveyor roller industry, I have deep understanding your needs.

This expertise enables me to quickly understand your needs and recommend you the most suitable roller for your project. Let’s contact and work together to achieve your goals with confidence and reliability.

Project Construction

We have rich project experience and can tailor cost-effective rollers for your project based on your needs, providing excellent quality at a low cost.

Common Questions

Frequent Asked Questions.

We have listed some questions you may ask. If you have more inquiries about our products, you can send an inquiry to contact us.

We offer a range of tube materials for our Conveyor Roller, including stainless steel, carbon steel , carbon steel with melting PU cover, carbon steel with plastic sleeve, PVC and alluminum alloy. Each material is selected for its specific operations, such as food industry, 3C industry and wood industry etc, to best suit the requirements of different construction projects.

Absolutely! You can choose the sizes, driven ways, surface treatment and even sprocket materials. We make sure everything fits just right for your project.

We utilize Power Press Assembly Technology for assembling, which eliminates play between components small gap. Before shipping, we will check the debt while roller rotating, meanwhile will check roller roundness for avoidding misalignment

We offer a range of driven ways for our Conveyor Rollers, including polymer single or double sprocket, steel single or double sprocket, grooved, poly-vee and motorized. Each way is selected for its specific handling solution, such as poly-vee and round belt fit for anti-static environment, steel sprocket for heavy-duty conveying solution, machined roller fit for belt conveyor avoidding mistracking. Each roller has own features to suit the requirements of different construction projects.

We can supply you EXW, FOB, CIF, DDU.

Also 1 year quality warranty with replacement service

Customer Feedback

With years of exceptional customer service experience, we deeply understand your needs and have built a strong reputation for reliability. Your feedback is our top priority. Partner with us, and you’ll benefit from professional expertise and dedicated support

Are you searching for a reliable factory to catch your project ?

We offer a 1-year warranty with replacement service.

If any quality issues arise, we will guarantee a 100% refund.

Your satisfaction is our priority !

Email: sales@yiyunauto.com

Contact us Now !

We can provide you free CAD design to match your unique operation and product with 1 year warranty and free change if having quality issue.